Hobart Welding Wire Chart . Stickout (electrode extending from the tip of the contact tube). For thin metals, use a smaller diameter wire. Keep a 1/4 to 3/8 in. Hobart submerged arc welding catalog. Hobart® filler metals are recommended for use with all miller® power sources, wire feeders, guns and torches because of their consistent high quality and performance. We offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for your. Resources available always provide model name and serial/style number. View and download hobart ironman 230 owner's manual online. Gas metal arc (mig) welding, flux cored arc (fcaw) welding, arc welding power source and wire feeder. View technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for.

from enginelistqlintuitions.z14.web.core.windows.net

Hobart® filler metals are recommended for use with all miller® power sources, wire feeders, guns and torches because of their consistent high quality and performance. View and download hobart ironman 230 owner's manual online. Resources available always provide model name and serial/style number. For thin metals, use a smaller diameter wire. Stickout (electrode extending from the tip of the contact tube). We offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for your. View technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for. Gas metal arc (mig) welding, flux cored arc (fcaw) welding, arc welding power source and wire feeder. Keep a 1/4 to 3/8 in. Hobart submerged arc welding catalog.

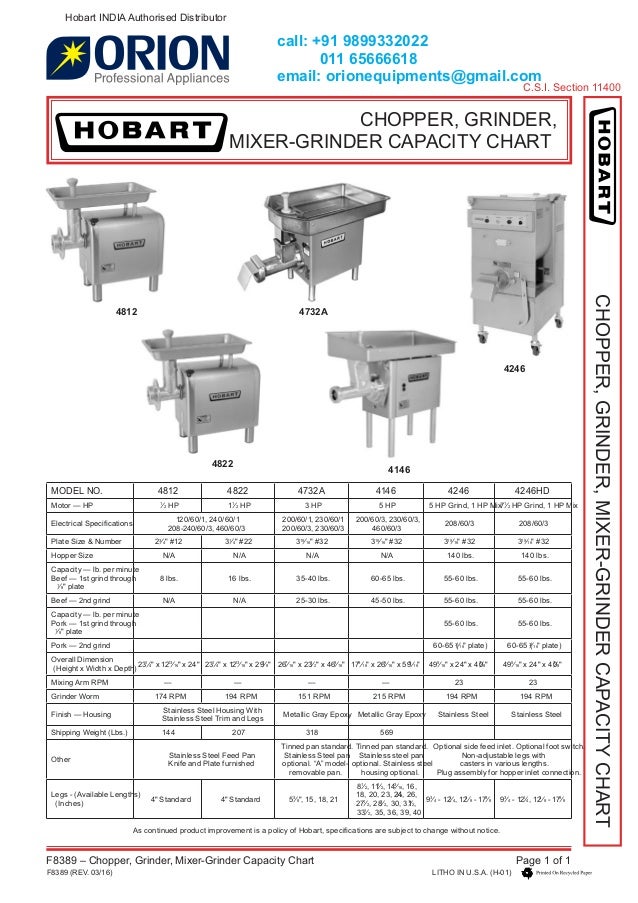

Hobart Mixer Sizes Chart

Hobart Welding Wire Chart View technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for. View and download hobart ironman 230 owner's manual online. Hobart submerged arc welding catalog. Resources available always provide model name and serial/style number. Stickout (electrode extending from the tip of the contact tube). Keep a 1/4 to 3/8 in. We offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for your. View technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for. Hobart® filler metals are recommended for use with all miller® power sources, wire feeders, guns and torches because of their consistent high quality and performance. For thin metals, use a smaller diameter wire. Gas metal arc (mig) welding, flux cored arc (fcaw) welding, arc welding power source and wire feeder.

From enginelistqlintuitions.z14.web.core.windows.net

Hobart Mixer Sizes Chart Hobart Welding Wire Chart Hobart submerged arc welding catalog. Keep a 1/4 to 3/8 in. Hobart® filler metals are recommended for use with all miller® power sources, wire feeders, guns and torches because of their consistent high quality and performance. View and download hobart ironman 230 owner's manual online. For thin metals, use a smaller diameter wire. Resources available always provide model name and. Hobart Welding Wire Chart.

From schematicscaldini.z21.web.core.windows.net

What Size Ground For 400 Amps Hobart Welding Wire Chart Stickout (electrode extending from the tip of the contact tube). For thin metals, use a smaller diameter wire. We offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for your. Gas metal arc (mig) welding, flux cored arc (fcaw) welding, arc welding power source and. Hobart Welding Wire Chart.

From circuitlibadducted.z14.web.core.windows.net

Millermatic 211 Aluminum Setup Hobart Welding Wire Chart Hobart submerged arc welding catalog. Resources available always provide model name and serial/style number. View technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for. For thin metals, use a smaller diameter wire. We offer a variety of helpful welding charts and guides that you can reference online, or download as a. Hobart Welding Wire Chart.

From www.pinterest.com

Welding Wire Size Chart Welding wire, Welding cable, Welding Hobart Welding Wire Chart View technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for. Keep a 1/4 to 3/8 in. Gas metal arc (mig) welding, flux cored arc (fcaw) welding, arc welding power source and wire feeder. We offer a variety of helpful welding charts and guides that you can reference online, or download as. Hobart Welding Wire Chart.

From www.northerntool.com

Hobart MIG Welding Wire — ER70S6 Carbon Steel, .035in., 2Lb. Spool Hobart Welding Wire Chart Hobart® filler metals are recommended for use with all miller® power sources, wire feeders, guns and torches because of their consistent high quality and performance. View technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for. We offer a variety of helpful welding charts and guides that you can reference online, or. Hobart Welding Wire Chart.

From harrietlee.z19.web.core.windows.net

Hobart Welding Wire Chart Hobart Welding Wire Chart Hobart® filler metals are recommended for use with all miller® power sources, wire feeders, guns and torches because of their consistent high quality and performance. View and download hobart ironman 230 owner's manual online. Resources available always provide model name and serial/style number. Stickout (electrode extending from the tip of the contact tube). For thin metals, use a smaller diameter. Hobart Welding Wire Chart.

From manuallibrarymonardas.z14.web.core.windows.net

Millermatic 211 Aluminum Setup Hobart Welding Wire Chart Hobart submerged arc welding catalog. For thin metals, use a smaller diameter wire. We offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for your. Keep a 1/4 to 3/8 in. View and download hobart ironman 230 owner's manual online. Gas metal arc (mig) welding,. Hobart Welding Wire Chart.

From www.pinterest.com

Available career positions at Hobart Welding School Welding schools Hobart Welding Wire Chart Keep a 1/4 to 3/8 in. View and download hobart ironman 230 owner's manual online. Hobart submerged arc welding catalog. View technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for. Resources available always provide model name and serial/style number. For thin metals, use a smaller diameter wire. Gas metal arc (mig). Hobart Welding Wire Chart.

From gracesutton.z13.web.core.windows.net

Hobart Welding Rod Chart Hobart Welding Wire Chart View technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for. Keep a 1/4 to 3/8 in. Stickout (electrode extending from the tip of the contact tube). Gas metal arc (mig) welding, flux cored arc (fcaw) welding, arc welding power source and wire feeder. Hobart submerged arc welding catalog. Resources available always. Hobart Welding Wire Chart.

From www.northerntool.com

FREE SHIPPING — Hobart Handler 140 FluxCore/MIG Welder — 115V, 140 Amp Hobart Welding Wire Chart Hobart® filler metals are recommended for use with all miller® power sources, wire feeders, guns and torches because of their consistent high quality and performance. We offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for your. Hobart submerged arc welding catalog. Gas metal arc. Hobart Welding Wire Chart.

From weldingrods.com

Welding Rod Chart Hobart Welding Wire Chart View and download hobart ironman 230 owner's manual online. We offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute, or post for your. Gas metal arc (mig) welding, flux cored arc (fcaw) welding, arc welding power source and wire feeder. Hobart submerged arc welding catalog. Keep a. Hobart Welding Wire Chart.

From www.mscdirect.com

Hobart Welding Products MIG Welding Wire; Industry Specification Hobart Welding Wire Chart Resources available always provide model name and serial/style number. View technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for. View and download hobart ironman 230 owner's manual online. We offer a variety of helpful welding charts and guides that you can reference online, or download as a pdf to print, distribute,. Hobart Welding Wire Chart.

From www.chainsawjournal.com

Best MIG Welder for the Money — Top Rated Models Hobart Welding Wire Chart View technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for. Stickout (electrode extending from the tip of the contact tube). Keep a 1/4 to 3/8 in. Hobart submerged arc welding catalog. Resources available always provide model name and serial/style number. We offer a variety of helpful welding charts and guides that. Hobart Welding Wire Chart.

From schematicpartparches.z13.web.core.windows.net

Hobart Wire Welder Parts Hobart Welding Wire Chart View technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for. View and download hobart ironman 230 owner's manual online. Stickout (electrode extending from the tip of the contact tube). Gas metal arc (mig) welding, flux cored arc (fcaw) welding, arc welding power source and wire feeder. Resources available always provide model. Hobart Welding Wire Chart.

From elisejoyce.z13.web.core.windows.net

Weld Filler Metal Selection Chart Hobart Welding Wire Chart Stickout (electrode extending from the tip of the contact tube). Hobart® filler metals are recommended for use with all miller® power sources, wire feeders, guns and torches because of their consistent high quality and performance. Resources available always provide model name and serial/style number. View and download hobart ironman 230 owner's manual online. Hobart submerged arc welding catalog. Gas metal. Hobart Welding Wire Chart.

From www.wiringstech.com

Hobart Welder Wiring Diagram Wiring Technology Hobart Welding Wire Chart Stickout (electrode extending from the tip of the contact tube). Resources available always provide model name and serial/style number. Hobart® filler metals are recommended for use with all miller® power sources, wire feeders, guns and torches because of their consistent high quality and performance. Keep a 1/4 to 3/8 in. Gas metal arc (mig) welding, flux cored arc (fcaw) welding,. Hobart Welding Wire Chart.

From wiringdiagram.2bitboer.com

hobart welder wiring diagram Wiring Diagram Hobart Welding Wire Chart View technical guides for guidance on welding various metals and selecting the right hobart brothers filler metal solution for. Hobart® filler metals are recommended for use with all miller® power sources, wire feeders, guns and torches because of their consistent high quality and performance. View and download hobart ironman 230 owner's manual online. Stickout (electrode extending from the tip of. Hobart Welding Wire Chart.

From dishcuss.com

Miller Mig Welding Chart photos and vectors Hobart Welding Wire Chart Hobart submerged arc welding catalog. For thin metals, use a smaller diameter wire. View and download hobart ironman 230 owner's manual online. Gas metal arc (mig) welding, flux cored arc (fcaw) welding, arc welding power source and wire feeder. Keep a 1/4 to 3/8 in. Hobart® filler metals are recommended for use with all miller® power sources, wire feeders, guns. Hobart Welding Wire Chart.